Project:(2sets 30tons Semi-Continuous pyrolysis Plant )

Working video:

https://youtube.com/shorts/Sn3hSIlY7Cg?si=-VnVLoCfKfZosH4Z

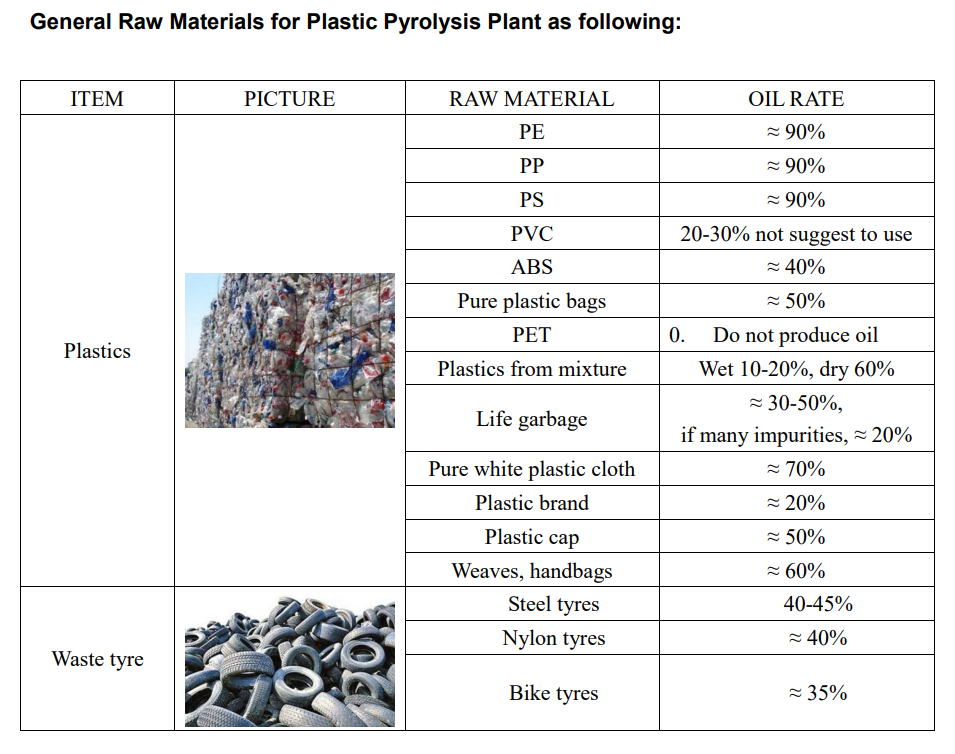

Raw materials:waste rubber blocks (1-2 cm), rubber powder, waste plastics, etc.

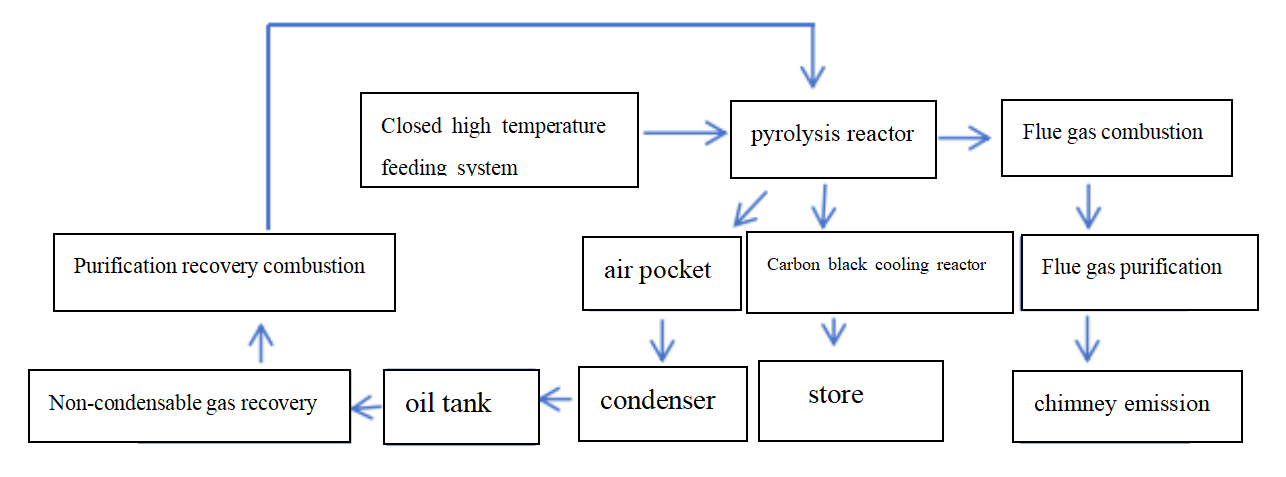

Process flow:

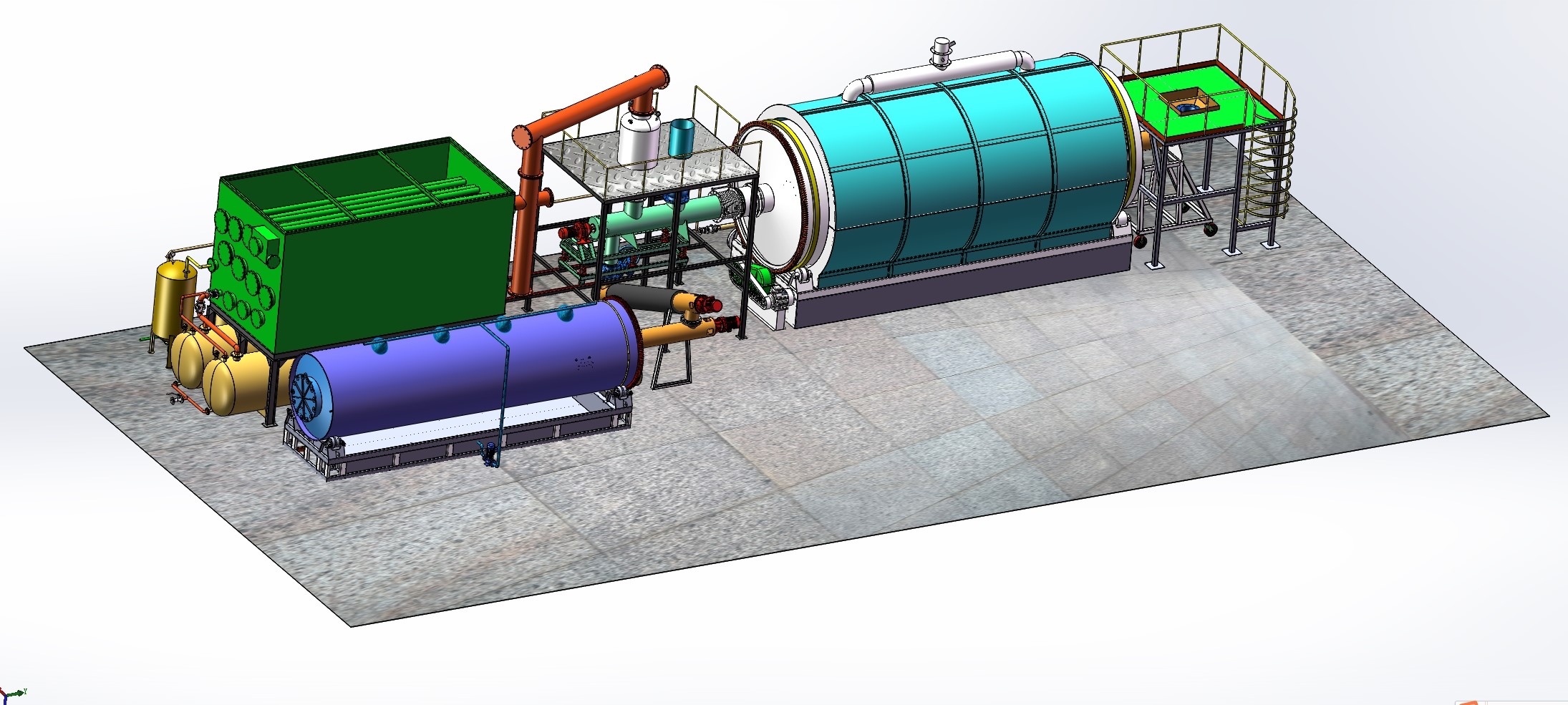

Three-dimensional diagram

Product advantages:

1.Gas dynamic seal: high temperature flue gas flows through the channel between the insulation shell and the pyrolysis reactor , through the pyrolysis reactor wall to achieve heat transfer with the material. The trough-type pressure-controlled structure + heat-resistant flexible packing sealing technology can reduce the external cold air entering the channel, save energy and improve thermal efficiency.

2.Oil and gas dynamic seal: With the rotation of the pyrolysis reactor, the material inside moves to the front of the the pyrolysis reactor and is heated to generate oil and gas, etc., while the expansion of pyrolysis reactor is extended to front end of pyrolysis reactor during the heating process. The combined flexible dynamic sealing technology is adopted to ensure that there is no smoke leakage or oil leakage occur during the operation of the equipment, and to realize the isolation of the material pyrolysis environment and the external environment during the rotation of the equipment.

3.Fully enclosed feeding and slag discharging system, environmentally friendly pollution.

4.The automatic anti-coking technology, using scraper coke cleaning plant and heat conduction spherical beads combined to prevent coking in the pyrolysis reactor.

5.Heat transfer technology, heat accumulator and guide separator: The guide separator and heat accumulator are set up in the annular cavity formed between the shell and the furnace, which not only improves the residence time of the flue gas in the heating flue, but also increases the turbulence intensity of the flue gas and improves the heat transfer efficiency.

6. Non-condensable gas is purified and pressurized, and the non-condensable gas removes acid gas and a small amount of oil substances through alkali washing. The purified non-condensing gas is separated by gas-liquid and used after pressurization

7.Fully enclosed feeding and slag discharging system,realizes high-temperature feeding and high-temperature slag discharging, with carbon black cooling reactor to realize continuous production of equipment, with fast production and high efficiency.

Equipment features:

1.The pyrolysis reactor runs smoothly with no abnormal noise or obvious beating.

2.The pyrolysis reactor adopts gear transmission, and the front and rear wheel belts and supporting wheels are made of forgings or castings that have been heat treated to increase pressure resistance and wear resistance.

3.The pyrolysis reactor can be regulated by frequency conversion; The speed of the reducer can be adjusted.

4.The complete set of pyrolysis equipment can operate normally under the environmental conditions of -10~40℃ and relative humidity ≤85%.

5.Necessary inspection shall be carried out before the equipment leaves the factory and the inspection certificate shall be issued.

6.Fully sealed high temperature feed and slag removal system.